Bacteria Screen Print

This project was for a Biological Design class that asked students to find overlap between their design interests and biological innovations learned throughout the semester. My final project was focused around developing a bacterial screen printing ink.

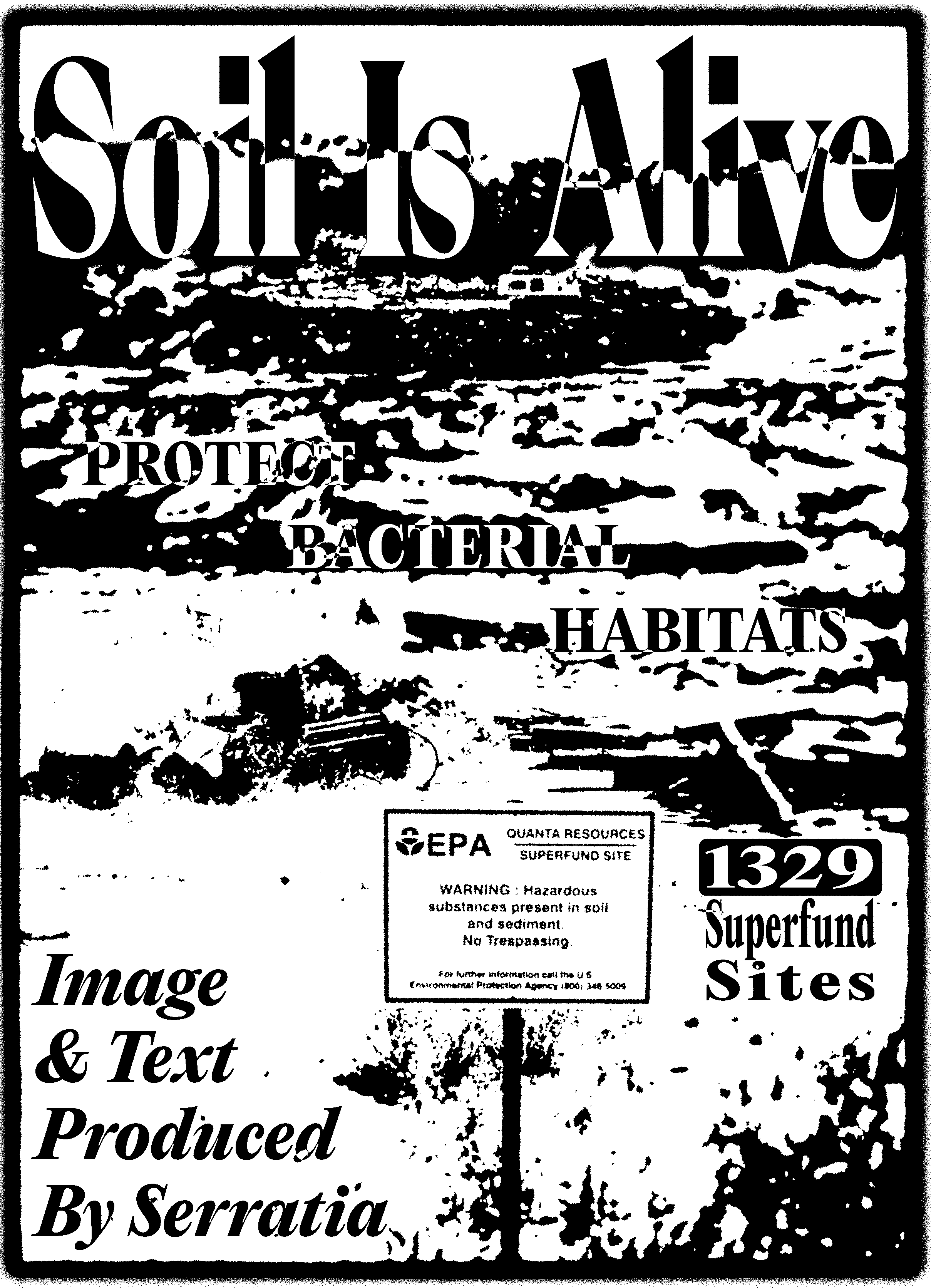

Digital Design

My goal for this project was to experiment with bacterial printing and to create a viable alternative to screen printing ink using biological materials. I researched bacterial printing more and found that most projects were used to showcase the potential of alternative ink but did not necessarily advocate for its use over traditional inks. Reflecting upon how I could adjust my project to align more with my academic interests, I drew a connection from using an ink alternative to a material ethics class I was taking, which focused on the life cycle of materials starting from how they’re sourced, used, and discarded during a project. A term I learned in this class that stuck out to me was “Superfund site” which are sites designated by the EPA as “the nation’s most contaminated land and… environmental emergencies, oil spills and natural disasters.” Typically, screen printing inks are made using oil-based inks that require nonrenewable materials. I saw a connection between using bacteria, which live in soil to facilitate life, as an alternative for an oil-based product, a material consistently responsible for multiple environmental contamination disasters. I thought it would be an effective message to make a piece where bacteria are used to raise awareness for their own habitat’s contamination while acting as the solution. Superfund sites served as a single large example of the overarching issue of environmental contamination.

Bacteria Solution

The Bacteria used for this project was Serratia because of its abundance and deep red color. After allowing the bacteria to proliferate for 3 weeksin 150 mL of LB agar solution it was dark enough to begin printing with.

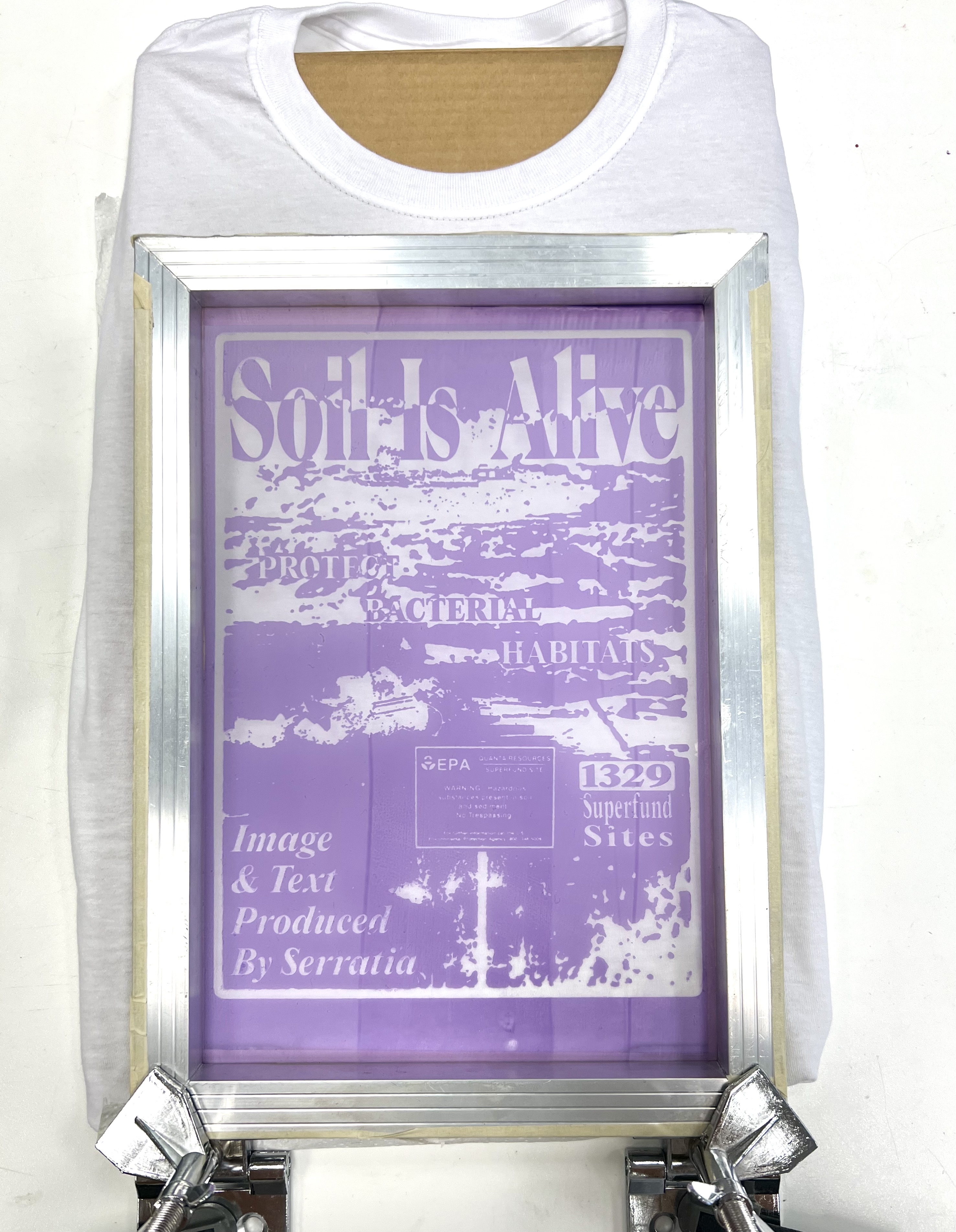

Burned Screen

Since LB agar is too liquid to screen print properly, I had to add a thickener to make the solution act like ink in the screen. I used cornstarch at various concentrations to find the right visocity for the ink. This had the unanticipated effect of turning the ink pink instead of red, but the final product was a functioning ink with bacteria as the primary dye.

Final Product